Perforated structural idlers offer our clients the opportunity to optimize their costs and build in a shorter time. The different drilling patterns adapt to the specific needs of each project.

By bolting and overlapping each other, they allow the construction of buildings to be faster and the structural elements to work more efficiently.

One more option to optimize execution and construction procedures, in addition to structural qualities, its practical stowage allows savings in freight and delivery capacity on site.

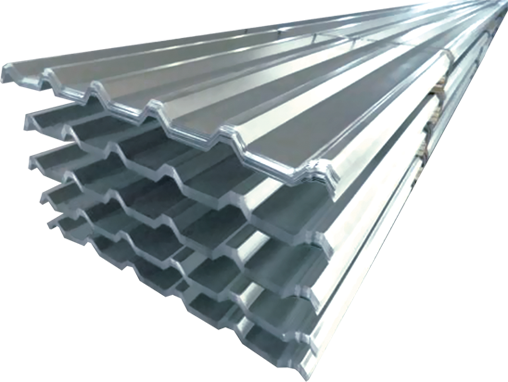

Trapezoidal profiled sheeting made in the plant through a stationary rolling machine from Ternium steel coils, designed to be used as a roof with exposed fasteners.

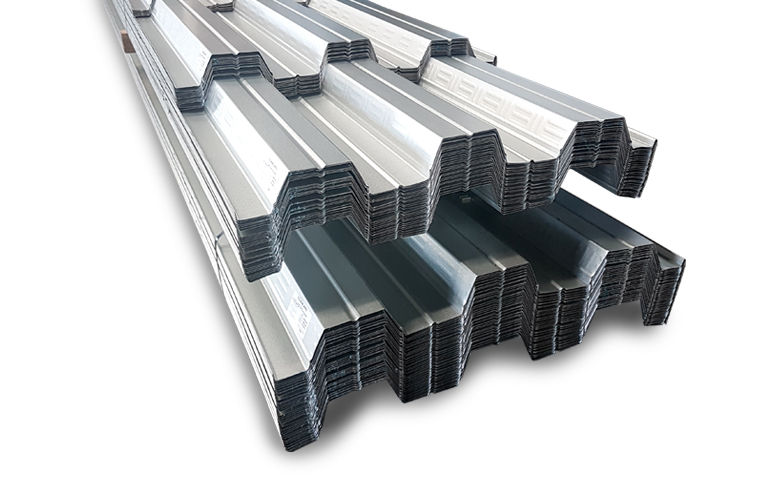

Metal mezzanine system that uses a rolled steel profile designed to work perfectly with concrete and form mezzanine and roof slabs. Manufactured under the quality standards of ANSI (American National Standards Institute) and SDI (Steel Deck Institute).

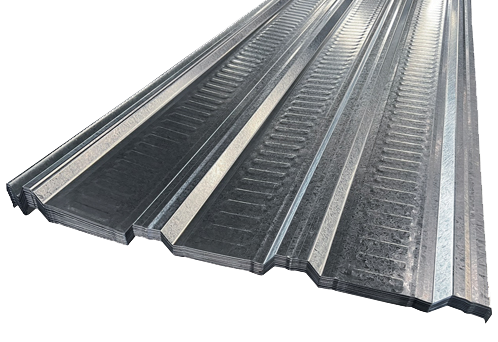

Corrugated profile manufactured in a plant using a stationary roll forming machine from a Ternium steel coil, designed as an exposed fixing wall. The material for the sheet can be Galvanized, Zintroalum, or Coated..

Cutting strips from 48" to 60" steel coils. 10 gauge cutting capacity.